Vacuum Transfer Systems: Industry Solutions

The vacuum transfer system is an advanced material handling system that has found significant use in a wide range of industries. This innovative technology works by producing a vacuum within a closed pipeline, allowing for the efficient and contamination-free flow of products such as bulk solids, powders and granules.

One of the vacuum powder transfer systems major advantages is its ability to handle bulk solid, powder and granules with accuracy, minimal wastage, and care. Whether in pharmaceuticals, food processing, battery, resin or chemical industry, the system is designed to ensure product integrity while limiting dust emissions—an important requirement in industries where product purity is vital. A vacuum transfer system helps industries improve powder handling processes with a focus on quality and safety.

How does it work?

The vacuum transfer system uses suction to move dry materials, such as powders and granules, through a closed pipeline with precision and efficiency. This process utilizes vacuum pressure to remove the necessity for mechanical components and manual work. It relies on the fundamental principles of creating a pressure differential between the source point (where materials are stored) and the destination point (where materials are needed). As the vacuum is applied, materials are gently drawn into the pipeline and transported to their intended location.

Aishin Industrial Corporation, a pneumatic conveying system manufacturer, is well known for its expertise in material and powder transfer systems. We specialize in vacuum conveying systems for powder and granules and have expertise in developing and providing systems that meet various material handling needs for companies in India and across the globe.

Benefits of Aishin Vacuum Transfer System

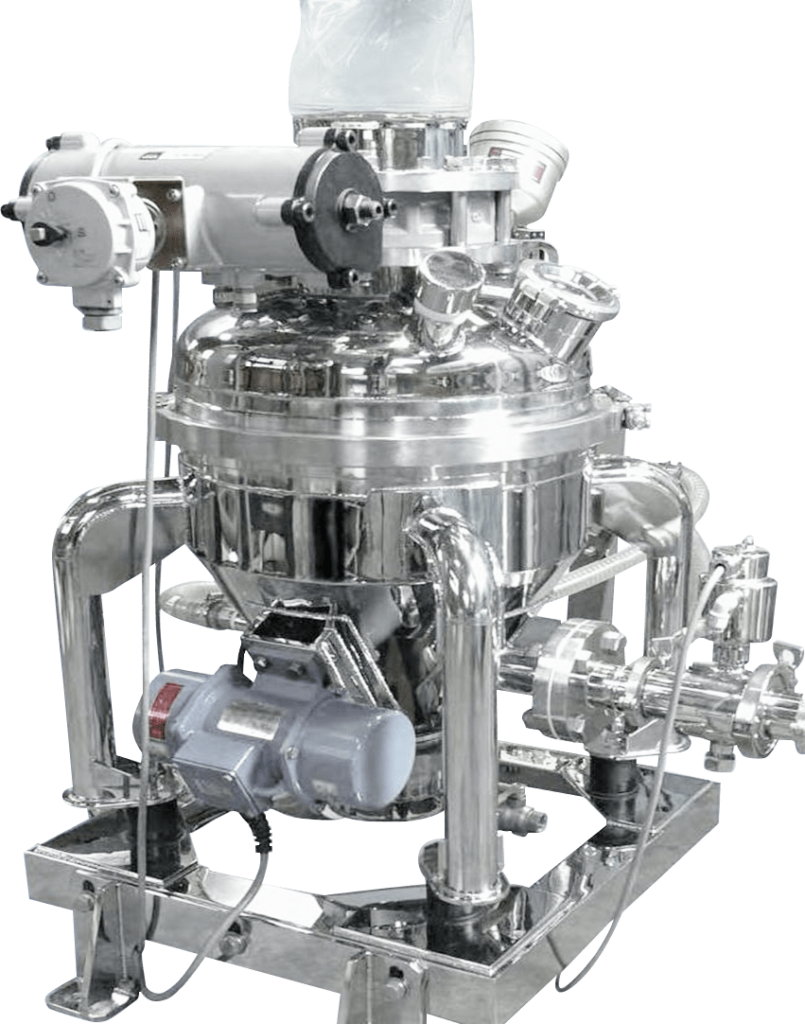

Boxer

- Transfer rates up to 4000 Kg/hr can be achieved.

- Bulk densities as high as 2.5 g/cc and as low as 0.2g/cc can be conveyed.

- Modular design with easy opening and cleaning

- Flap type discharge valve for easy discharge

Dense Phase Transfer System

- Stable transfer is possible for powders and granular that is difficult to transfer by suction like highly adhesive and cohesive fine powder etc.

- It is possible to set high or low pressure transfer, high or low density transfer

- Air quantity required is less and filter area can be reduced

- It is a complete discharge type and there are no remains in the equipment

- Suitable for long distance transfer

Volkmann

Volkmann vacuum conveying systems from Germany are the best in class solution for vacuum conveying of various types of powders, granules, tablets & capsules. Volkmann offers a wide variety of products for Pneumatic conveying.

- Vacuum conveying with electrical as well as venturi pumps

- High containment closed loop vacuum conveying with up to OEB Level 5

- Transfer rates up to 5000 Kg/hr

- Various types of Anti corrosive, Anti Abrasive coatings available

- ATEX models available

- CIP available

Applications

Iron manufacturing, Steel manufacturing, Metal, Fiber, Grains, Pellets.

The perfect Japanese engineering for closed loop transfers

F.A.Q.

Have any Question?

Vacuum transfer systems work by creating a pressure differential between two points, typically using a vacuum pump. This pressure difference allows materials to be conveyed through a network of pipes or tubing to their desired destination.

Vacuum Material Transfer Systems can handle a wide range of materials, including powders, granules, pellets, and other dry powders. They are versatile and suitable for various industrial applications.

Maintenance requirements vary depending on the system’s complexity and usage. Regular inspections, cleaning, and servicing of components such as filters, pumps, and valves are typically needed to ensure optimal performance.

These systems maintain a sealed environment to prevent contaminants from entering the process. The vacuum suction ensures that powders are transferred without exposure to the surrounding atmosphere.

Vacuum transfer systems can help reduce material wastage, minimize dust emissions, and improve overall process efficiency, which can lead to environmental benefits such as reduced energy consumption and fewer emissions.