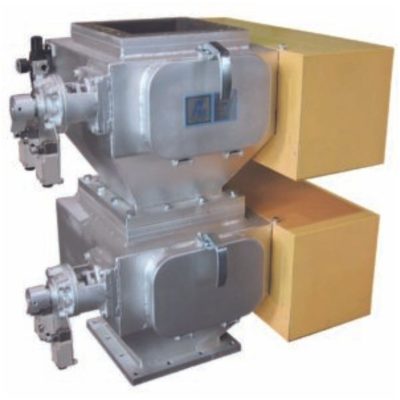

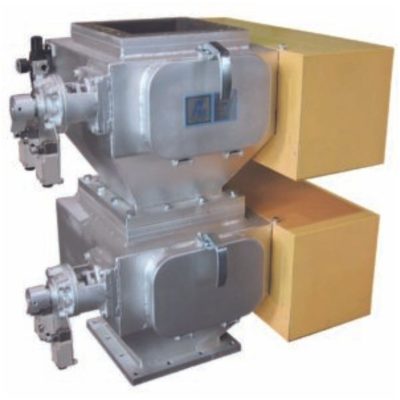

Double Flap Dampers : Fragile and Non-Fragile Transfer

Double flap dampers, also known as twin flap dampers, are specialized control devices used in transfer systems to moderate the flow of powders and granular materials. These dampers are made up of two flaps that can be adjusted to control the powder flow volume and direction.

Working Process of Double Flap Dampers

Double flap dampers are designed to maintain a smooth flow of materials, preventing clogging and ensuring efficient material transfer. The structure of a double flap damper includes several key components, such as the casing, chute, valve plate, shaft, bearing box, gland packing, bearing unit, and an inspection point. Each of these components plays a specific role in ensuring the proper functioning of the damper.

A double flap damper operates by using two flaps that open and close one after the other. Initially, the first flap opens to allow material passage, then closes. Following that, the second flap opens to maintain the material transfer and subsequently closes. This sequential flap movement regulates material flow, preventing blockages or disruptions in the transfer process.

Importance of Double Flap Dampers

Double flap dampers are essential for maintaining exact control over powder movement, minimizing unwanted surges or blocks that could affect production. These dampers are essential components of industrial process control systems, ensuring that powders are delivered consistently and efficiently to the desired destination.

Features

- Precision powder flow management.

- Adjustable dual-flap design for control.

- For removal of dust collector or cyclone

- Sanitary flap damper available

Benefits

- Improved process efficiency

- Prevent clogging

- Reduced downtime risks

Features

- Precision powder flow management.

- Adjustable dual-flap design for control.

- For removal of dust collector or cyclone

- Sanitary flap damper available

Benefits

- Improved process efficiency

- Prevent clogging

- Reduced downtime risks

Applications

Aishin Industrial Corporation Double Flap Dampers provide precise material flow control, especially when working with powders prone to clogging. These dampers have two independent flaps that can be adjusted to fine-tune the flow rate and maintain optimal process conditions. Aishin’s double flap dampers improve material handling, reducing disruptions and boosting production efficiency in various industries like pharmaceuticals, chemicals, food industries and others.

F.A.Q.

Have any Question?

Standard Double Flap Dampers are designed for general industrial applications, while Sanitary Double Flap Dampers are specifically designed for industries where cleanliness and hygiene are crucial, such as food processing and pharmaceuticals.

Yes, double-flap dampers can effectively control both powder and granule flow in various industrial processes.

Double flap dampers have two flaps, allowing for more precise control compared to single flap dampers. It is useful for pneumatic transfer of fragile and non- flowing products.

Double-flap dampers can be partially opened to create a self-cleaning effect. This prevents material from accumulating and clogging the discharge chute by allowing some material to flow while breaking up potential blockages.