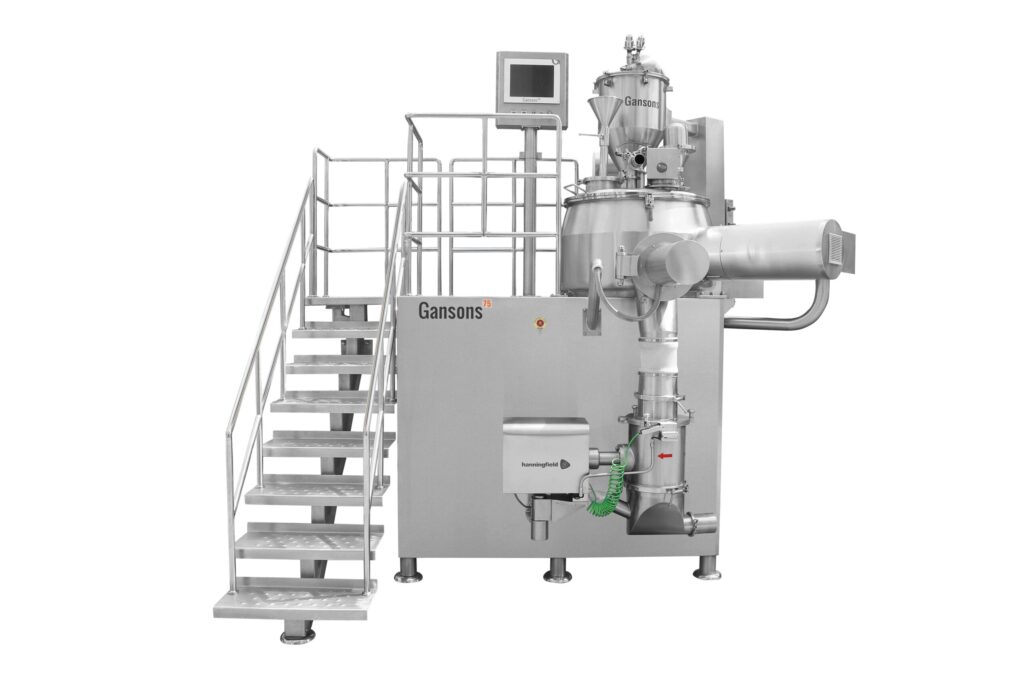

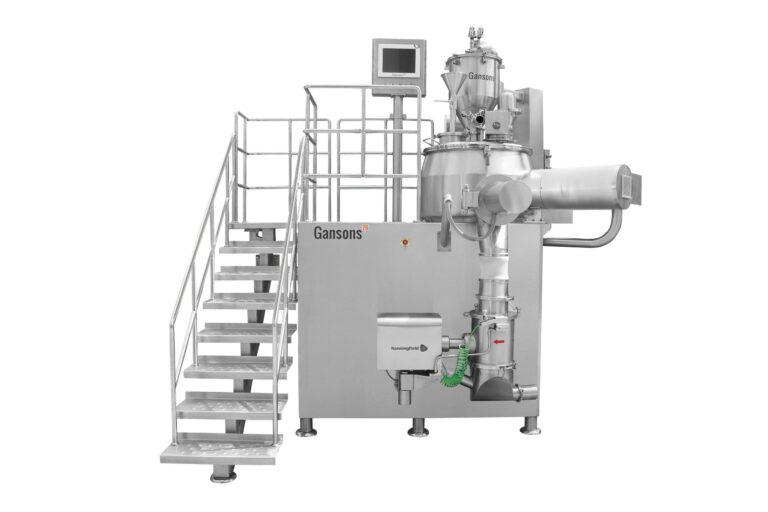

Gansons High Shear Mixer Granulator

High Shear Mixer Granulator is used in various industries to efficiently blend and granulate powders, ensuring the production of high-quality solid dosage forms. This innovative technique combines the benefits of a high shear mixer with a granulator, creating a single, versatile unit capable of performing both blending and granulation tasks seamlessly. It includes granulation-reproducibility, risk–free granulation, and process control in granulation.

Working Principle of High Shear Mixer Technology

The working principle of the HSMG involves addition of liquids (binders) to the dry powder mixture. The impeller generates high shear forces within the process bowl, resulting in intense mixing and deagglomeration of the powders. Simultaneously, the chopper works to break down any large agglomerates and distribute the binder fluid evenly.

As the mixing process continues, the powders absorb the binder, and granules start to form. The impeller’s design ensures that the granules achieve the desired density and uniformity. The combination of shear and compression forces during mixing contributes to the successful wet granulation process.

The Gansons High Shear Mixer Granulator (HSMG) is a top notch wet-granulation technology solution in the industry. It enables quick and efficient mixing, kneading, and granulation, resulting in uniform, high-density granules with batch to batch consistency and reproducibility. Every component of the Gansons HSMG is engineered precisely to address processing problems and prevent unexpected downtime.

- Encountering issues like bimodal powder behavior? We have the solution.

- Dealing with black particles in your granules? The Gansons HSMG can solve that.

- Worried about irregular endpoints? Rest assured; the Gansons HSMG eliminates that concern.

Gansons High Shear Mixer Granulators ensures that wet granulation becomes efficient, predictable, scalable, and hassle-free.

The units are utilized in manufacturing facilities subject to regulatory oversight by US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (in various countries), and others. Upon request, our equipment can be customized to adhere to CE, UL, ATEX, EU 2006/42/EC, ISO, and IEC standards. The High Shear Mixer Granulator is tailored to meet the unique requirements of tablet formulation and is designed to accommodate the drying needs of pharmaceuticals, formulations, and bulk drugs.

Features of High Shear Mixer

- Accurate end-point detection

- Equipment customization available for CE, UL, ATEX, EU 2006/42/EC, ISO, and IEC standards.

- High Shear Mixer Granulator designed for tablet formulation and pharmaceutical drying.

- Tailored for pharmaceuticals, formulations, and bulk drug manufacturing.

- Regulatory compliance with US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH, and more.

Benefits

- Efficient Mixing and Granulation

- Reduced Processing Time

- Improved Granule Quality

- Dust Control

- Process Quality, efficiency and repeatability

Key Information

- Iwata™ design impeller and chopper have been developed in collaboration with Japanese mixing technologists. These design advancements have demonstrated a significant improvement in mixing efficiency and eliminated challenges such as the bimodal behaviour of powders.

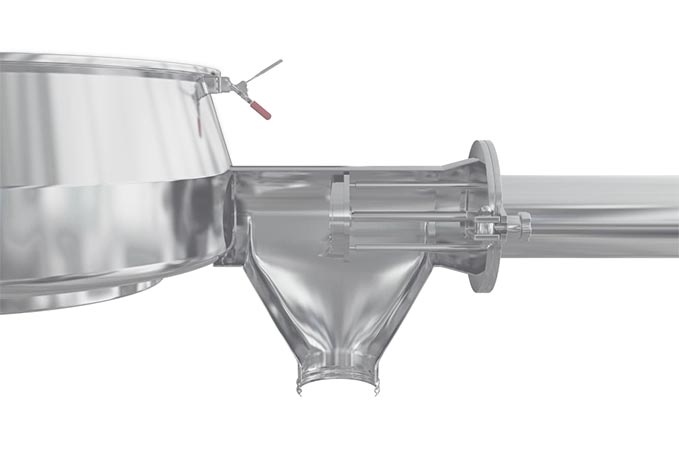

Iwata™ Chopper performs the dual function of binder distribution and deagglomeration

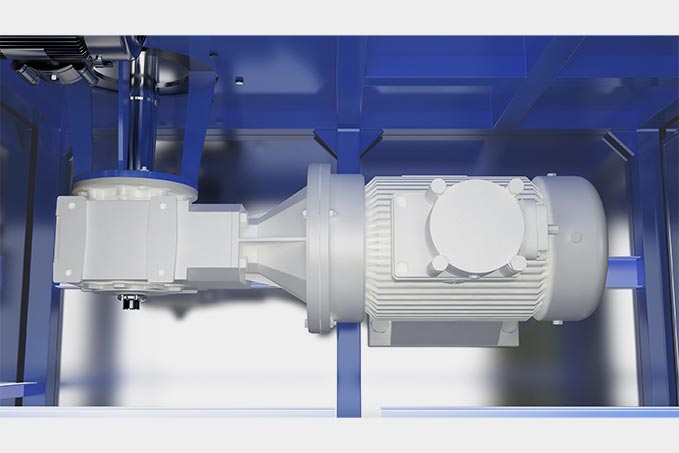

Electro-mechanical components provide consistently reliable end-point detection

Gansons’ proprietary mechanical seals prevent the ingress of any particles into machine shaft

Up to 12-bar shock pressure resistant designs

Process Bowl

Impeller

Chopper

Cleaning and Maintenance

• 360-degree spray nozzles facilitate washing in place, and can be recipe driven

Gearbox

Intelligent Automation

Construction Features

• ATEX rated (flame proof) designs based on zoning requirements.

• All components are compliant with a Zone 2/22 production environment.

• All contact parts in SS 316L or FDA approved materials (gaskets, seals, filter bags etc.)

Duo Seal System

Capacity Range: 1L to 2000L

Certifications