Industrial Material Dryer Machine

Drying is an essential industrial process that has applications in various industries to eliminate moisture from powdered materials. This procedure is very critical to obtaining products having good quality, efficiency, and safety standards in various industries.

Industrial Material Dryer Machine

Drying is an essential industrial process that has applications in various industries to eliminate moisture from powdered materials. This procedure is very critical to obtaining products having good quality, efficiency, and safety standards in various industries.

The Drying Process

The drying process is necessary for powdered material for removal of moisture as per the required limits to make it suitable for various applications. To achieve this, materials are dried in drying equipment by using hot air passing from different mediums like steam and electric heaters. The primary purpose of drying is to reduce the moisture content in the powder because moisture can lead to problems like clumping, spoilage, or reduced shelf life of powdered materials. By using drying equipment, heat is applied to the powder, which causes the moisture to evaporate. The hot air circulates through the material, effectively and removing the liquid content. This process is critical and has applications in various industrial segments such as food, pharmaceuticals, API, agrochemicals and chemical manufacturing, where precise moisture levels are crucial for product quality, stability and standards.

Aishin along with partnership with Gansons supplies fluid bed dryer machines designed specifically for drying powders and granules. You can rely on this efficient equipment to meet your drying needs as we have sold this equipment to regulated pharmaceutical companies across the globe.

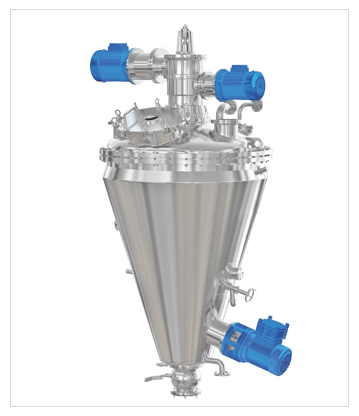

Powder drying is vital in industries like pharmaceuticals, food processing, and chemicals. Uniform and efficient drying is crucial for quality and meeting industry standards. Equipment supplied by Gansons are Nauta mixers and fluidized bed dryers.

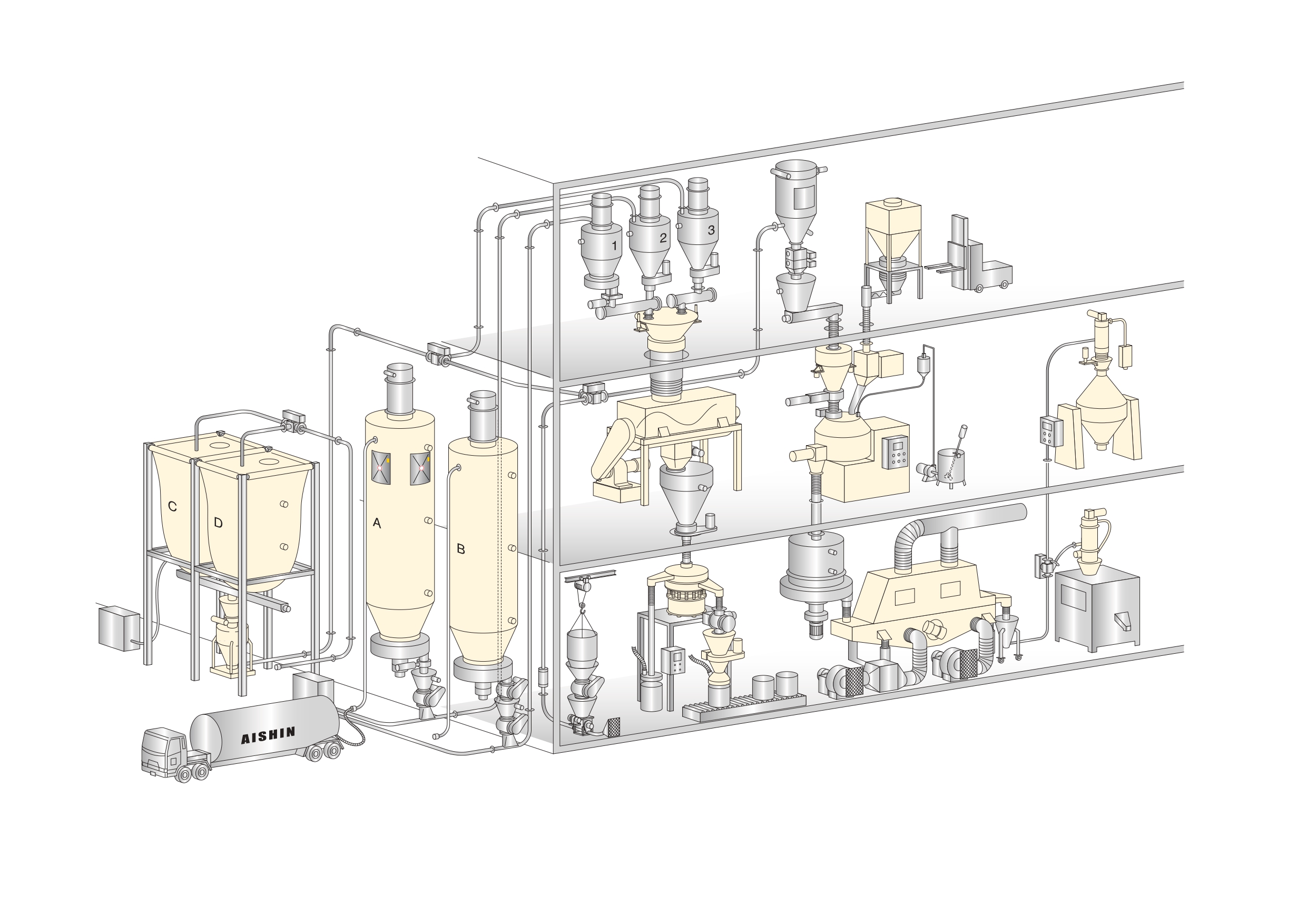

Experience the precision of Japanese engineering in bulk powder handling and storage solutions

Your Journey towards Precision begins here

Flow Characteristics

We understand the flow characteristics of the powder and provide custom solution to the problem of material flow

Equipment Design

Design with Japanese engineering emphasizing attention to detail, quality and rigorous standards and disciplined approached to design.

Processing Rate

Advantages

- Nauta mixer prevents powder clumping and ensures even drying.

- Suitable for diverse powder types, including heat-sensitive materials.

- The conical vessel’s ample surface aids efficient heat transfer.

- Design reduces residue and simplifies cleaning.

Advantages

- Enables rapid drying with great particle-fluid interaction.

- Maintains even temperature distribution in the bed.

- Suitable for drying at lower temperatures.

- Available in various sizes for different production scales.