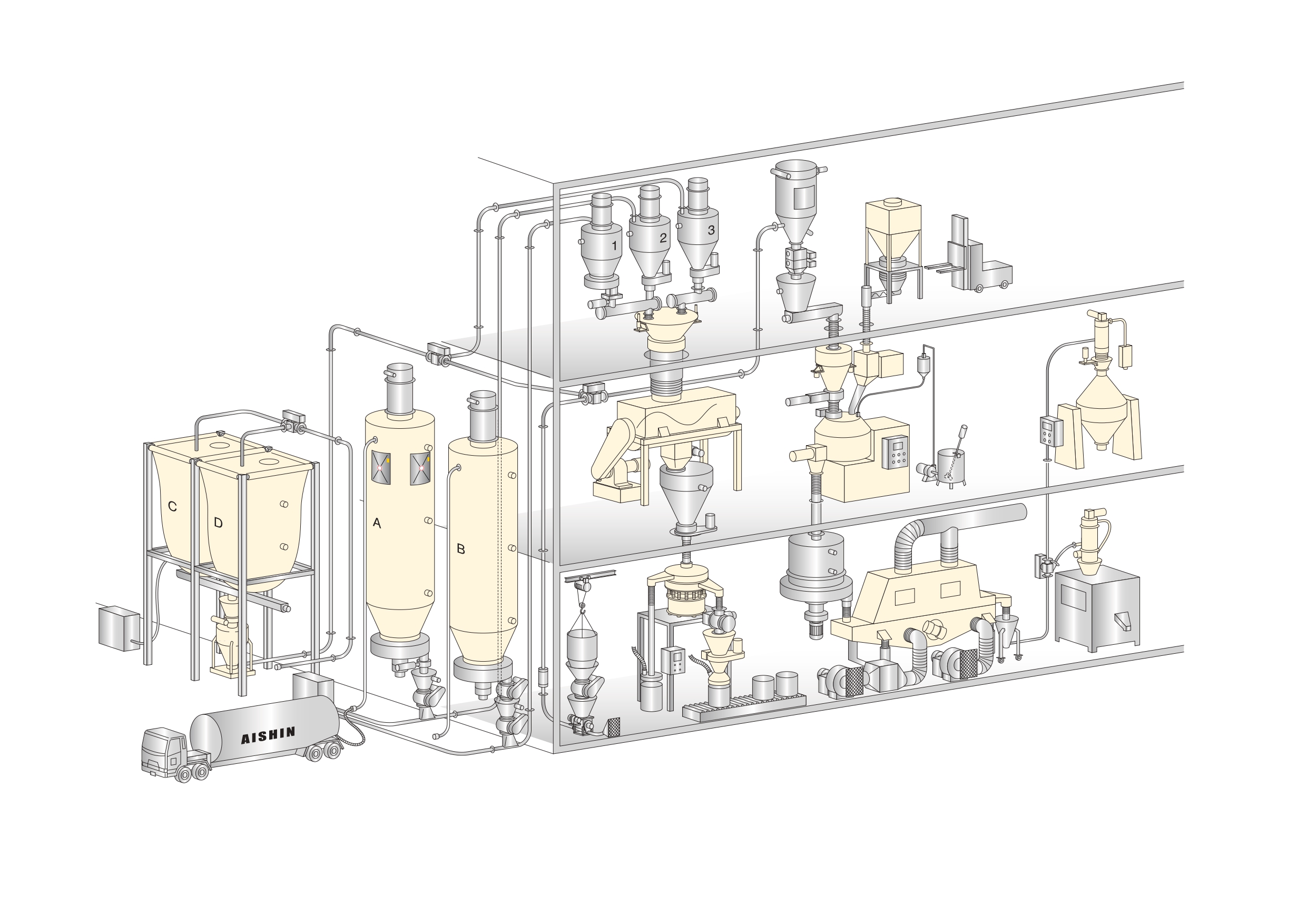

Mixing & Granulation Process

In the pharmaceutical, chemical, and food industries, mixing and granulation processes play an important role in ensuring the quality and consistency of products.

How does mixing work?

Mixing and granulation are essential processes in the pharmaceutical, food, and chemical industries to create homogeneous blends and uniform granules from powder materials. Various equipment, such as Nauta, HSMG, Diffusion Blender, Ribbon Mixer, and Planetary Mixers, are used for these processes. Whether it’s pharmaceutical compounds, food additives, or chemical substances. This step ensures that the components are evenly distributed, preventing clumping or segregation. Granulation, on the other hand, involves combining fine powder particles into larger, more manageable granules, improving flowability and compressibility for subsequent processing. Both mixing and granulation play a crucial role in product quality and are necessary steps in the production of various products across these industries.

Here's how Gansons equipment works in mixing and granulation

Gansons Nauta

A Nauta® Mixer is an industrial mixing equipment used for blending powders and granules without aggressive agitation. It’s ideal for pharmaceutical mixing due to its low shear and energy usage, ensuring homogeneity and precision. It’s commonly used in powder blending and delicate operations.

- Can be combined with inert gas or air percolation drying.

- Easy solvent recovery.

- Mixing and reaction of products in an aqueous phase at temperatures above 100°C.

- No damage to heat sensitive products.

Gansons HSMG

Gansons High Shear Mixer Granulator (HSMG) is widely used in various industries for blending and granulating powders, enhancing the production of high-quality solid dosage forms. It combines high shear mixing and granulation capabilities into a single efficient system, making it ideal for manufacturers seeking improved production efficiency and product quality.

- Advanced automation with regulatory compliance controls.

- cGMP-compliant safe cleaning and validation.

- Oversized agglomerates are effectively de-lumped/distributed.

Diffusion Blender

Gansons Diffusion Blender is designed to achieve uniform mixing of dry powders or granules. It operates using a unique diffusion mixing principle instead of mechanical agitators or blades. By rotating the powdered materials, it leverages diffusion to create a uniform mixture, ensuring ingredient homogenization.

- Precise placement of intensifiers for homogenous mixing.

- Includes railing for enhances safety.

- Various capacities ranging up to 5000 litres are available.

Planetary mixers

Planetary mixing involves the simultaneous rotation and orbiting of the mixing tool, ensuring consistent and even mixing of powdered materials. It is used for precise and homogeneous mixing in applications such as dough preparation, cream emulsification, cosmetic formulation production, etc.

- Planetary motion of the impeller effects homogeneous incorporation and mixing of excipients.

- Built to withstand high viscosity products.

- Easy access to mixing bowl for rapid and convenient cleaning.

Ribbon Mixers

A Ribbon Mixer, also known as a Ribbon Blender Machine, is an industrial equipment used for uniformly mixing and blending dry materials through the rotation of spiral ribbons within a cylindrical container.

- Double stirrer shaft for quick mixing.

- Minimal clearance between main body and blade reduces residue.

- No deposit of material on the stirring blade and residue after discharge is very less