Gansons Multi Mill

A Multimill, is a highly robust industrial particle size reduction equipment employed in various purposes such as granulation, shredding, pulverizing, and delumping. This is widely used in pharmaceutical manufacturing, chemical processing, food production, and other industries where particle size reduction and material homogenization are crucial.

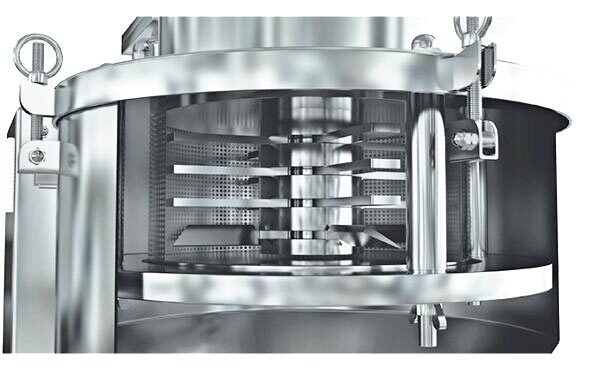

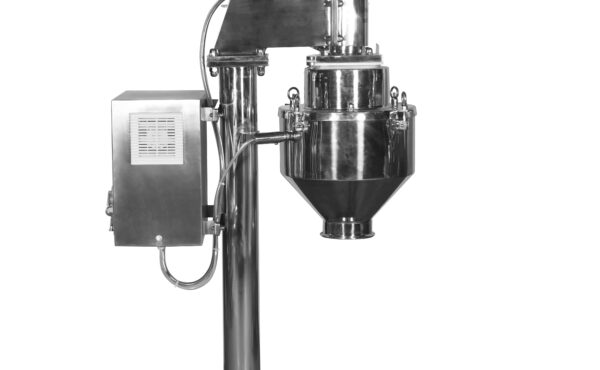

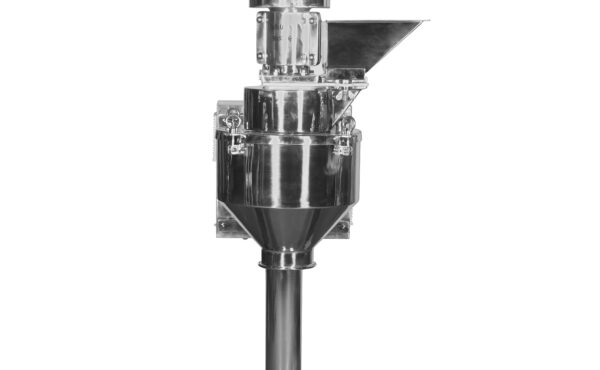

Gansons MultimIll works by utilizing multiple. blades or knives to comminute or reduce the size of solid materials. The machine’s operation involves a combination of cutting, shearing, and crushing actions. The materials to be processed are fed into the funnel-like hopper, and they pass through the milling chamber where the rotating blades shred and disintegrate them into smaller particles. The processed materials then exit through a sieve, allowing for precise control over the desired particle size.

Enhancing Oral Dosage Formulation with Gansons Multimill

- Particle size reduction is a critical process in the formulation of oral dosage forms. Particle size distribution has an effect on the physical properties of finished dosage forms properties such as flow, content uniformity, and hardness. Impact the finished dosage form.

- More importantly, particle size influences the pharmacodynamics of the finished product.

- The Gansons multi mill is an effective processing solution for sizing solid particles or lumps to smaller particle sizes, providing a narrow particle size distribution.

Features and Benefits

Reversible blade rotation for granulation or pulverization purposes.

Interchangeable blades to suit the process and material

Wide range of screen types and perforation size to suit a broad range of applications

- Efficient particle size reduction.

- Customizable particle size.

- Simple cleaning and upkeep.

Applications

Chemical, APIs, Battery Food, Cosmetics

Gansons holds a prominent position as a global multimill manufacturer, with installations in over 40 countries. The equipment is installed in manufacturing facilities regulated by the US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (various countries), AND OTHERS.

Benefits

- Uniform particle sizing.

- Reduced waste, better efficiency.

- Compliance with regulatory standards

Capacity range: 60 Kg/hr to 500 Kg/hr

Certifications

F.A.Q.

Have any Question?

Multi Mill Machines find extensive use in pharmaceutical manufacturing for granulation and tablet formulation. They are also employed in the chemical and food industries for various milling and mixing applications.

In the pharmaceutical industry, a Multimill is crucial for granulation and size reduction of raw materials and active pharmaceutical ingredients (APIs). It ensures uniform particle size, which is essential for tablet and capsule manufacturing.

It employs multiple blades or impellers that rotate at high speeds, creating a turbulent milling action. This ensures thorough blending and uniform distribution of ingredients.

Multi Mills are useful for grinding, milling, and homogenizing food ingredients, ensuring product consistency and quality.

Multi Mills can be used for both batch and continuous production processes.

Regular maintenance may involve checking and lubricating moving parts, inspecting screens, and cleaning.

The impeller in a Multi Mill helps in the movement and reduction of materials by applying impact and shear force.

Get Quote for our Multi mill

Aishin specializes in developing customized solutions to fit your individual demands, while also optimizing performance and efficiency. Our dedication to quality and safety ensures a perfect fit for your specific needs, boosting your production capabilities.