Gansons Nauta Mixers: The Perfect Mix

A Nauta® Mixer is a type of low shear mixing equipment used primarily for handling powders and granules. It is designed to efficiently blend and homogenize dry materials by employing a unique operating principle that ensures thorough mixing without the need for aggressive mechanical agitation.

The Nauta® Mixer, commonly known as a mixer machine, is particularly useful in homogenous powder mixing, where homogeneity and consistency are crucial. Its design assures low shear and low energy, making it a great choice for the powder mixing machine, especially where precision is essential. Because of its versatility, it is commonly used in powder blending and other specialized operations where a delicate touch is required.

Working Principle of Gansons Nauta® Mixer

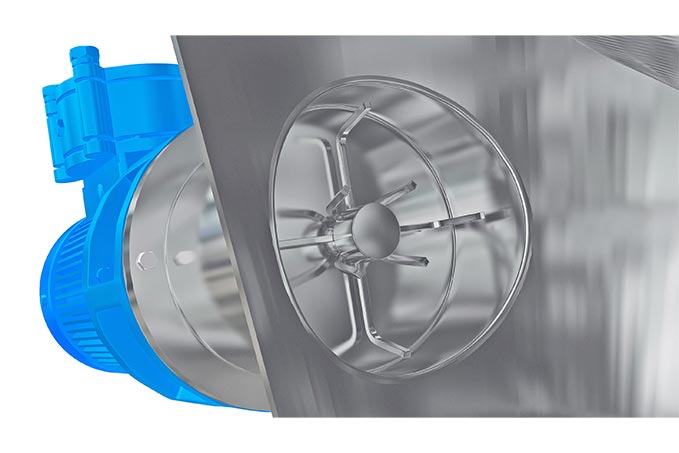

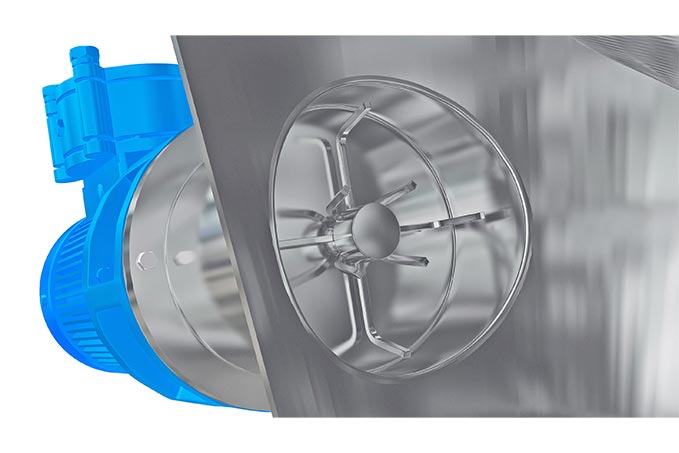

The Gansons Nauta® mixer includes a conical-shaped vessel for its blending process. This vessel design, with a wide top and a narrow bottom, promotes effective convergence of powder substances. Inside the vessel, a rotating screw facilitates a lifting and tumbling action, ensuring both radial and axial movement of the materials, resulting in thorough mixing. Additionally, the mixer features a spray nozzle for the controlled addition of liquids while the powder is being mixed. To eliminate any large agglomerates, a lump breaker is attached, and the system also has the capability for heating under vacuum conditions. Moreover, for quality checks, a sampling device is integrated into the mixer. Finally, at the bottom of the vessel, there is a discharger valve that efficiently releases the blended materials once the drying process is completed, ready for further processing.

Features and Benefits

Three Distinct Intermixing Currents

Sampling Device

Features and Benefits

Features and Benefits

Lump Breaker

Automation & Control

• Automated PLC based control system with touch screen HMI

Cleaning

• 360⁰ rotating spray balls for thorough cleaning

Fast Complete Discharge

Features and Benefits

Three Distinct Intermixing Currents

Sampling Device

Lump Breaker

Automation & Control

• Automated PLC based control system with touch screen HMI

Cleaning

• 360⁰ rotating spray balls for thorough cleaning

Fast Complete Discharge

Gansons Nauta® Processor [Mixing, Drying, Coating]

Powder coating on hard granules, homogenization of flavour or fragrance with powder, mixing of free-flowing powders with varying bulk densities, etc.

- Vacuum dryer

- Jacketing for heating or cooling

- Inert gas or air percolation

- Solvent recovery

Capacity: 10L to 10,000L

View Technical Document

Certifications

F.A.Q.

Have any Question?

Mixing equipment includes a wide range of machines such as ribbon blenders, Nauta mixers, and planetary mixers. Each type is designed for specific mixing needs, from powders to liquids, and is commonly used in various industries for blending and homogenizing materials.

A mixing machine for powder is designed to blend dry powders,and granules. It ensures uniform distribution and homogeneity, making it crucial in industries like pharmaceuticals, cosmetics, and the production of various powdered products.

Pharmaceutical mixing is crucial to ensure the uniform distribution of active ingredients and excipients in medication formulations. It helps maintain product efficacy, safety, and quality, meeting strict regulatory standards.

Industrial mixing machines play a vital role in manufacturing by ensuring consistent product quality, reducing production time, and minimizing material waste. They are used in diverse industries, from chemicals and plastics to food and pharmaceuticals.

The pharmaceutical industry relies on mixing equipment to produce consistent and high-quality medications. These machines ensure precise blending of active pharmaceutical ingredients (APIs) and excipients, leading to Product consistency and lesser wastage of raw materials.

Nauta Mixers are suitable for mixing a wide range of materials, including pharmaceutical powders, food ingredients, chemicals, and more.