Gansons Fluidised Bed Dryers:

Drying Multitude of Products

A fluidized bed dryer is a specialized machine designed for the efficient drying of granular, powdered, or particulate materials. The unique feature of a fluidized bed dryer is the process of fluidization, which plays an important role in its operation.

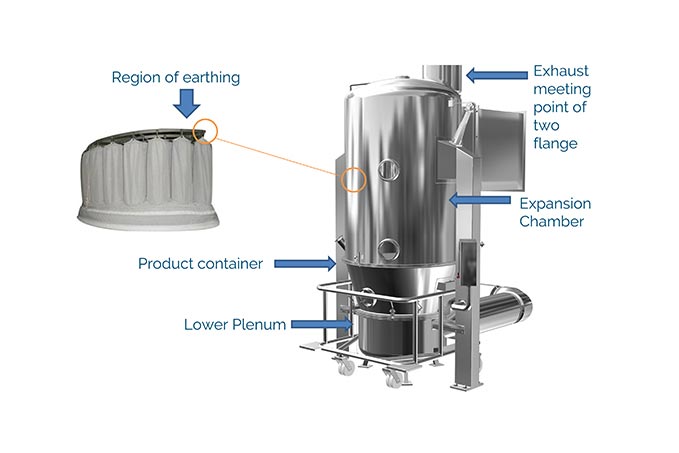

Gansons Fluidized Bed Dryer

Gansons Fluidized Bed Dryer (GFBD) is the preferred choice for fast and uniform drying of a multitude of products. The smart system incorporates quality features and an intelligent automation platform to deliver reliable, safe, and environmentally friendly performance over many years. The equipment is installed in manufacturing facilities that adhere to regulatory standards such as US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (various countries), and others. Upon request, the equipment can be tailored to meet CE, UL, ATEX, ISO, IEC standards. The GFBD can be designed to withstand shock pressures of up to 12 bar.

How Gansons Fluidized Bed Dryer Works

The Gansons FBD process starts by introducing the wet or moist material into the drying chamber, which is usually a bed of small particles of the material itself. Next, a stream of hot air is blown through the bottom of the chamber through AHU (air holding unit), creating a fluidized state. In this state, the solid particles in the bed begin to act like a fluid, resembling a mass of particles in motion.

As the heated air rises through the fluidized bed, it comes into direct contact with the wet material particles. This contact causes rapid heat transfer, leading to the evaporation of moisture from the material. The moist air is then removed from the system by passing through a pipe of the air handling unit (AHU), where it can be conditioned or filtered to maintain an eco-friendly environment. Meanwhile, the material powder remains inside the drying chamber, now free from moisture and ready for further processing

Features

- Increase air to particle contact

- Reduces drying time.

- Ensures uniform air flow

- Improves granules to fines ratio

- Capacity range: 10l to 1,500l

Fluidized Bed Dryer Benefits

- Reduces drying times significantly.

- Preserve product quality.

- Environmentally friendly drying process.

Cyklon® Air Distribution System (Patent Pending)

Unique 5-point electrical grounding system for product and operator safety

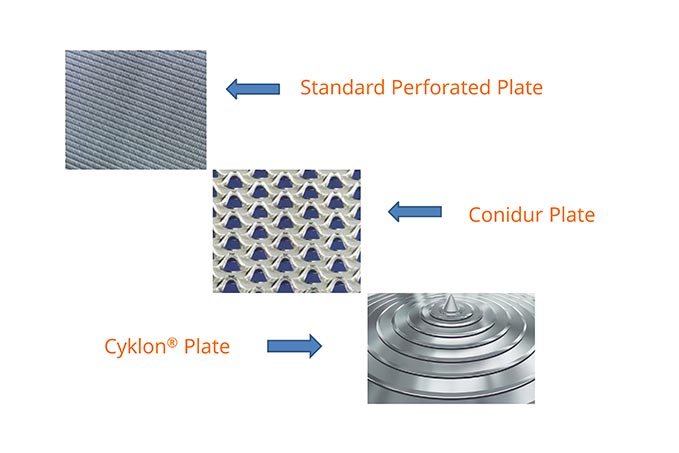

Air distribution plate types

Capacity Range: 10L to 1,500L

View Technical Document

Certifications

F.A.Q.

Have any Question?

A material dryer machine is an industrial equipment used to remove moisture or solvents from various materials. It works by blowing hot air or gas through the material, allowing the moisture to evaporate and leave the material dry.

Fluid dryer machines are versatile and can be used to dry a wide range of materials, including powders, granules, pellets, grains, and powdered chemicals.

Fluidization is typically achieved by introducing a flow of air or gas from the bottom of a container or vessel, causing the solid particles to become suspended and exhibit fluid-like behavior.

Fluidization is widely used in industries for tasks such as drying grains, coating particles with a thin layer of material, blending powders, and catalytic reactions due to its excellent mixing and heat transfer properties.

Fluidized bed dryers offer advantages such as uniform drying, high heat transfer rates, reduced drying times, and the ability to handle heat-sensitive materials, making them a popular choice in various industries.

Moisture is removed by passing hot air through the fluidized bed, which evaporates the moisture from the material.

Yes, they are commonly used in the pharmaceutical industry for drying and particle coating.