Conical Mill: Effective Size Reduction

Conical Mill: Effective Size Reduction

Conical mills, also known as cone mills or conical screen mills, are essential equipment in the field of size reduction and material management processes. These machines play an important role in industries requiring precision particle size reduction with tighter particle size distribution.

What is a conical mill?

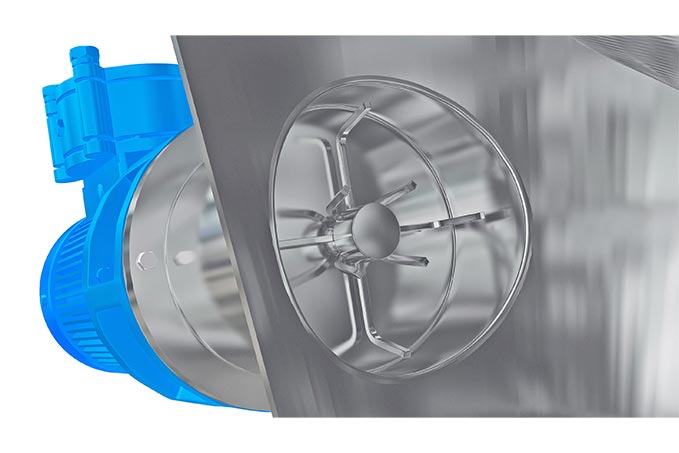

A conical mill is a specialized machine designed for the precise size reduction of various materials. It involves a rotor known as an impeller that rotates inside a conical screen. The material is fed into the cone mill machine, where it is reduced to the desired particle size primarily through impact, attrition, compression, and shearing.

The Hanningfield Uni-mill® u-series employs the widely recognized under-driven cone mill design that is currently prevalent in the industry. This design incorporates a gearbox-driven impeller that rotates within a screen. The primary method of particle size reduction utilized by the Hanningfield uni-mill® involves the compression and shearing of particles between the impeller and the surface of the screen.

The impeller and screen are designed conically, which facilitates the vortexing of the material during milling. Additionally, the Impeller operates with close tolerances to the screen. When material is fed into the conical mill through the hopper, the rotating impeller imparts a vortex flow pattern that generates centrifugal acceleration, forcing the product onto the screen surface. The particles undergo size reduction due to the impact of the impeller and attrition between the impeller and the screen surface. Particles are continuously delivered to the ‘action zone’ by gravity, resulting in instantaneous size reduction and 360º discharge.

The design of the conical screen allows for controlled particle size reduction, making it an ideal choice for applications where precise particle size control is essential.

Features and Benefits

Stainless Steel

FDA Compliant

ATEX / EX-Proof

No Metal-to-Metal Contact

Easy-Clean GMP Design

Fast Complete Discharge

Features and Benefits

Three Distinct Intermixing Currents

Sampling Device

Lump Breaker

Automation & Control

• Automated PLC based control system with touch screen HMI

Cleaning

• 360⁰ rotating spray balls for thorough cleaning

Fast Complete Discharge

Customise Your Mill

- Various mounting solutions are available (mobile frame, swing-arm, fixed post, hoist mounted etc.) and the mill can be customised with a selection of inlet and outlet configurations including hand-feed chute, valve assemblies, tri-clover connections, vacuum adaptors or any other bespoke design required for process integration.

- The design can be modified to include optional upgrade features including autoclave adaptor kit (detachable mill-head for sterilisation), temperature monitoring, CIP, WIP, pre-breakers, nitrogen purging and ATEX execution wherever applicable.

- All equipment can be supplied with full validation documentation (FS/DS, FAT, SAT, IQ/OQ) and 3.1 mill certificates to EN10204.

Types of impellers available: Square-arm and round-arm impellers

Impact is the main principle of the impeller for size reduction. In addition to that round arm impeller has a nip angle whereas a square arm impeller does not have a nip angle. A high nip angle causes particles to be grabbed inside the impeller and screen surfaces due to which compression force is exerted on the particle.

The Round-arm impeller is used mainly for aggressive dry milling where the fines requirement is less. This is due to the less retention time in the milling chamber of particles and less or negligible attrition of particles on the screen surfaces. As the Round-arm impeller exerts compression force it can be only used with screens with high tensile strength to prevent wear and tear of the screen. On the other hand square arm impeller has a flat face without any nip angle which causes the particle to drag over the screen surface causing attrition and size reduction of the particle. Here the fines generation is more. The square arm impeller can be used for dry as well as wet milling. Many different types of impellers can be manufactured depending on the physical properties and size requirement of the particles.

Features

- Stainless steel – 316l contact parts

- All seals FDA compliant (silicone, ptfe etc.)

- Atex (ex-proof) versions available

- Designed with an optimal, spacer-less gap (to avoid metal-to-metal contact)

- Optional features include detachable mill head for autoclave or CIP/WIP

- Rapid gravity discharge or side discharge.

Different types of screens available for dry milling and wet milling

The screen has round-shaped holes that can be used for Dry milling. When used with a Square bar impeller leads to attrition of product and with Round bar impeller leads to compression of product. The hole size ranges from 0.457 mm to 6.35 mm

This is a special type of round hole screen. As the screen hole becomes smaller the thickness of the screen decreases which helps to decrease the particle residence time in the screen hole. However, the thickness of the screen is very important to withstand the forces applied by the particle during size reduction. For providing tensile strength to the screen having thickness very less to withstand the forces applied by the particle during size reduction the main hole screen is bonded with the supportive screen. The diffusion-bonded screen is recommended for use only with a square arm impeller for fragile or brittle having less heat-sensitive products as the screen is available in very small hole sizes ranging from 0.152 mm to 0.457 mm (also available in normal Round hole screens).

This screen is made of a conidur sheet which has a cutting edge formed by the raised hole on one side of the screen hole which can be used for milling harder products where finer milling is required. The hole is moon-shaped with less open area suitable for less heat-sensitive material. The conidur hole screen is recommended to be used only with a square arm impeller to prevent deformation of the cutting edge by Round arm impeller compression force. The hole size is very small ranging from 0.152mm to 0.99 mm

This screen has square shape holes which are used for wet milling. The screen selection depends on the moisture and density of the wet mass. The Square hole screen is recommended to be used only with a square arm impeller. The hole size is very small ranging from 3.96 mm to 25.4 mm

This screen has rectangular-shaped holes that are used for wet milling and dumping. They produce large particle sizes as compared to square holes due to the horizontal length of the slotted screen being large as compared to a square hole screen.

Capacity: 200 Kg/hr to 4,000 Kg/hr

View Technical Document

Certifications

F.A.Q.

Have any Question?

A Conical Mill, also known as a Cone Mill Machine, is a pharmaceutical or industrial equipment used for particle size reduction and granulation. It features a conical-shaped rotor that rotates inside a conical screen, effectively reducing the size of materials.

A Cone Mill reduces particle size by effectively grinding and shearing the material between the rotor and the conical screen. This process results in finer and more uniform particle sizes.

Yes, Cone Mills are known for providing a narrow and consistent particle size distribution, which is crucial in industries like pharmaceuticals and food production.

Yes, Cone Mills can be integrated with material handling conveyors to streamline the process of feeding materials into the mill and discharging the processed material. This integration enhances efficiency and reduces manual handling.

Yes, some Cone Mills are designed to process wet materials, making them suitable for applications involving wet granulation or wet milling.

Yes, Cone Mills can be used for wet or dry granulation processes.

The impeller in a Multi Mill helps in the movement and reduction of materials by applying impact and shear force.