Precision-engineered powder transfer solutions

Precision-engineered powder transfer solutions

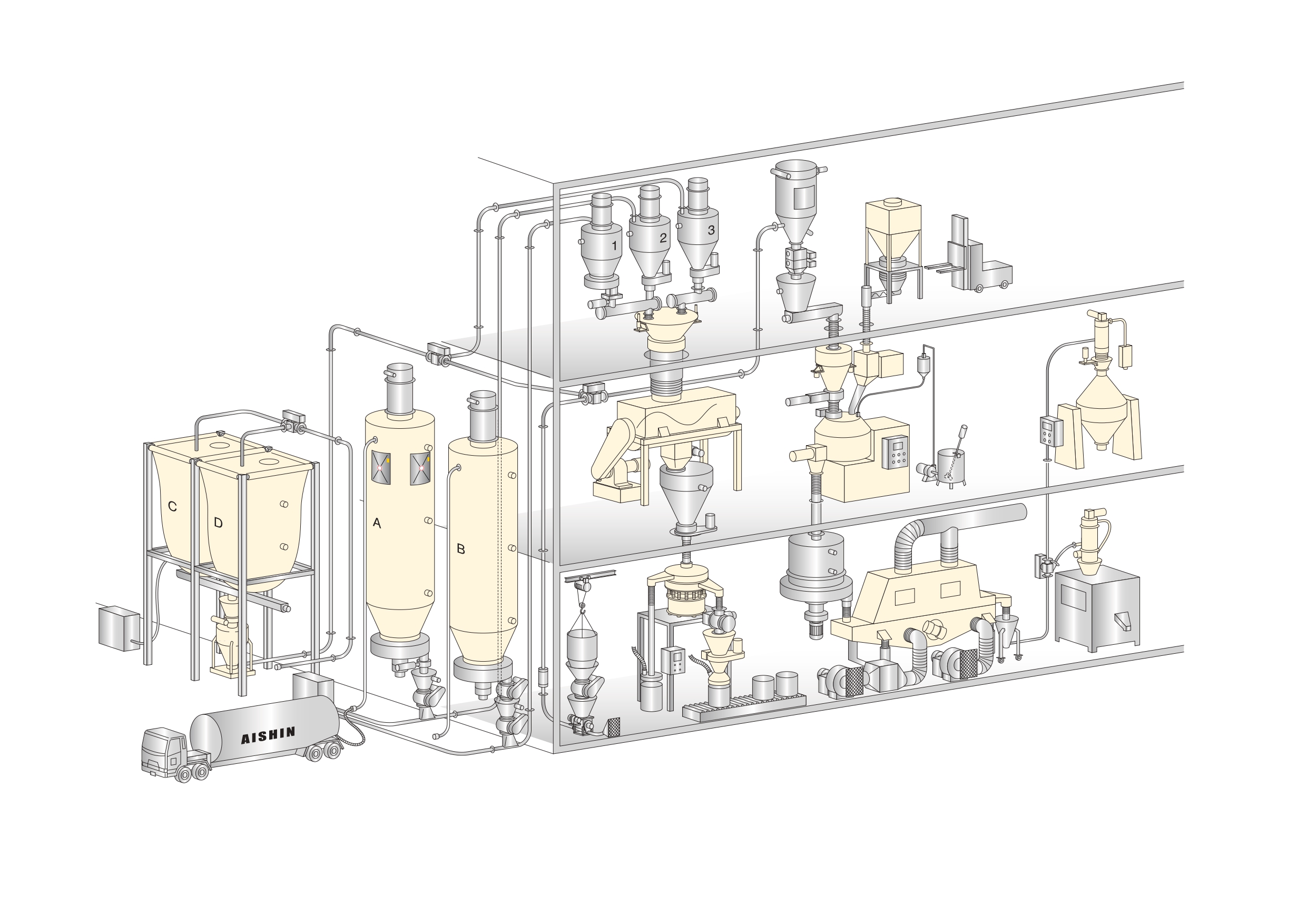

The powder transfer system efficiently moves powdered or granular materials within various industrial processes, proving to be a valuable asset in pharmaceuticals, food processing, and chemical manufacturing. It ensures contamination-free transfers, facilitating precise dosing, blending, and processing of substances like chemicals, pharmaceuticals, and food products.

In its design, the system carefully considers material characteristics, contamination control, and production efficiency to guarantee a seamless and reliable powder transfer. Key components, including conveyors, hoppers, and valves, collaboratively work through stages from loading to discharge, minimizing cross-contamination and enhancing production efficiency.

The powder transfer system operates based on both vacuum and pneumatic conveying systems. The dense-phase pneumatic conveying system enables controlled and efficient material transfer, while the vacuum transfer system utilizes negative pressure for conveying materials through pipelines with minimal energy consumption. This combination of technologies ensures optimal material handling, minimizing the risk of segregation and degradation.

Our Values -

Working the Japanese Way

We believe in delivering perfection in everything we do, which requires a focus on even the smallest details to ensure excellence in our products and services.

A relentless pursuit of perfection. Meticulous craftsmanship

Introducing AISHIN India - A Joint Venture with Gansons Private Limited

With 50 years of expertise in powder transfer, Aishin is a trusted provider of powder-handling solutions tailored to your needs. Our track record demonstrates our commitment to excellence across various industries. We understand each production environment is unique, offering unmatched customization options for seamless integration and optimal performance.

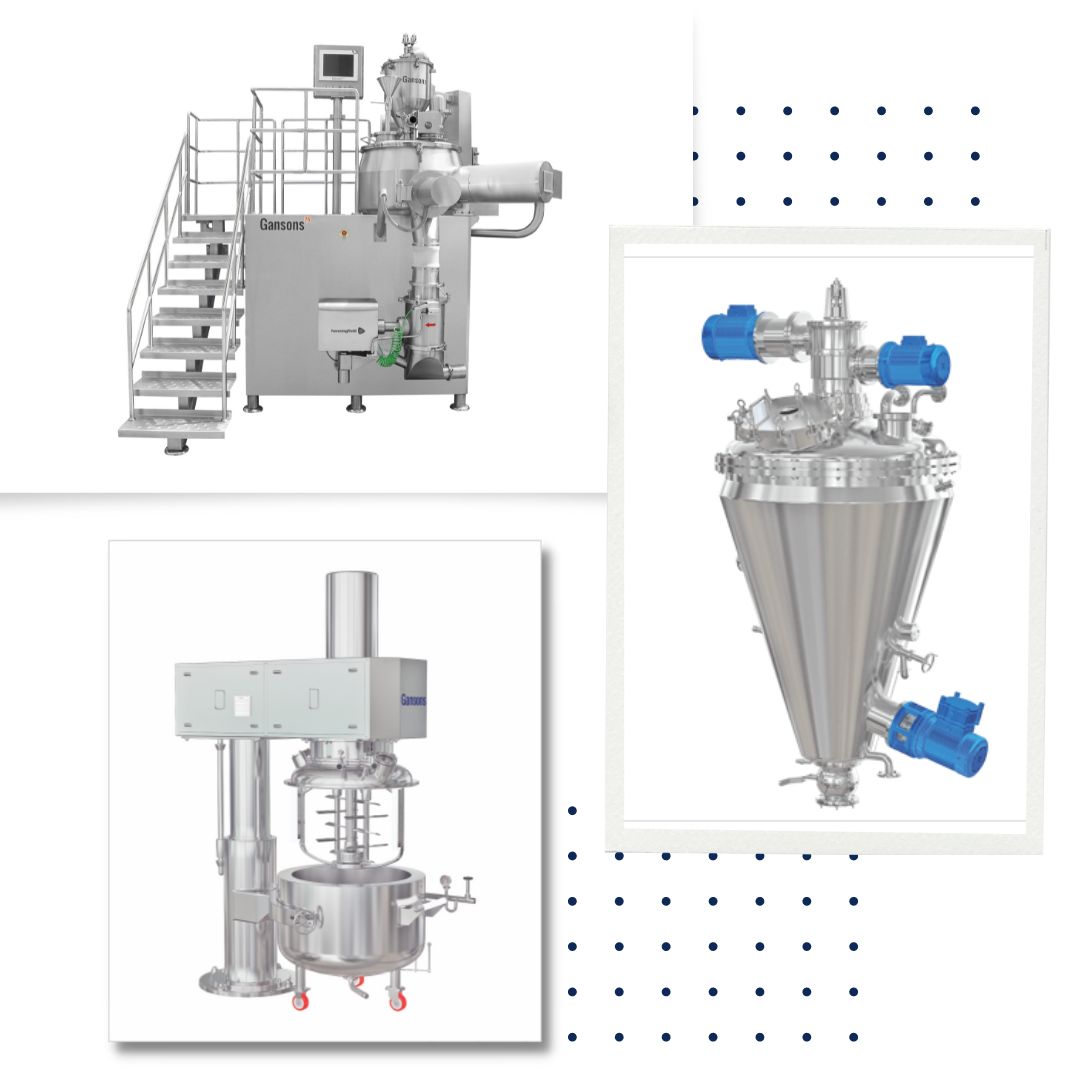

Our Japanese-engineered vacuum powder transfer system seamlessly integrates into material handling systems, prioritizing performance, durability, and ease of use for smooth and efficient material transfer. Whether you need specialized features or modifications, Aishin meets your production requirements.

Our Approach

Step – 01: Detailed Questionnaire for understanding current process

Step – 02: Layout study of the existing facility

Step – 03: Bottleneck identification and Equipment sizing

Step – 04: Designing process layout by the Japanese team

Step – 05: Techno-commercial Finalisation

Step – 06: Detailed planning for Manufacturing & Procurement

Step – 07: – Installation & Commissioning

Types of Powder Transfer System

Mechanical Transfer System

A mechanical transfer system, also known as a mechanical conveying system, transfers materials such as bulk solids, powders, granules from one point to another using machinery like belts, rollers, brackets, motors, etc.

Mechanical transfer systems are widely used in industries such as mining, automobiles, batteries, food, etc. where heavy high moisture content or cake-like material is to be transferred. These systems can take a variety of forms, such as bucket elevators and screw conveyors, chains, etc. Each customized for unique powder handling requirements.

Vacuum Transfer System

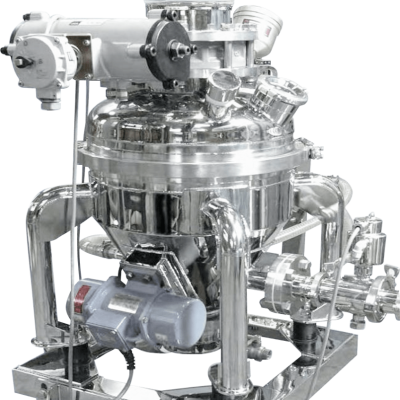

The vacuum transfer system is an advanced material handling system that has found significant use in a wide range of industries. This innovative technology works by producing a vacuum within a closed pipeline, allowing for the efficient and contamination-free flow of products such as bulk solids, powders and granules.

One of the vacuum powder transfer systems major advantages is its ability to handle bulk solid, powder and granules with accuracy, minimal wastage, and care. Whether in pharmaceuticals, food processing, battery, resin or chemical industry, the system is designed to ensure product integrity while limiting dust emissions—an important requirement in industries where product purity is vital. A vacuum transfer system helps industries improve powder handling processes with a focus on quality and safety.

Food Industry

Pharma & API industry

Electronics Industry

Plastics industry

Chemicals industry

Cosmetics Industry

Mining and Metals industry

FMCG

Contact Us

We are ready to help you with your Powder Transfer Solution.

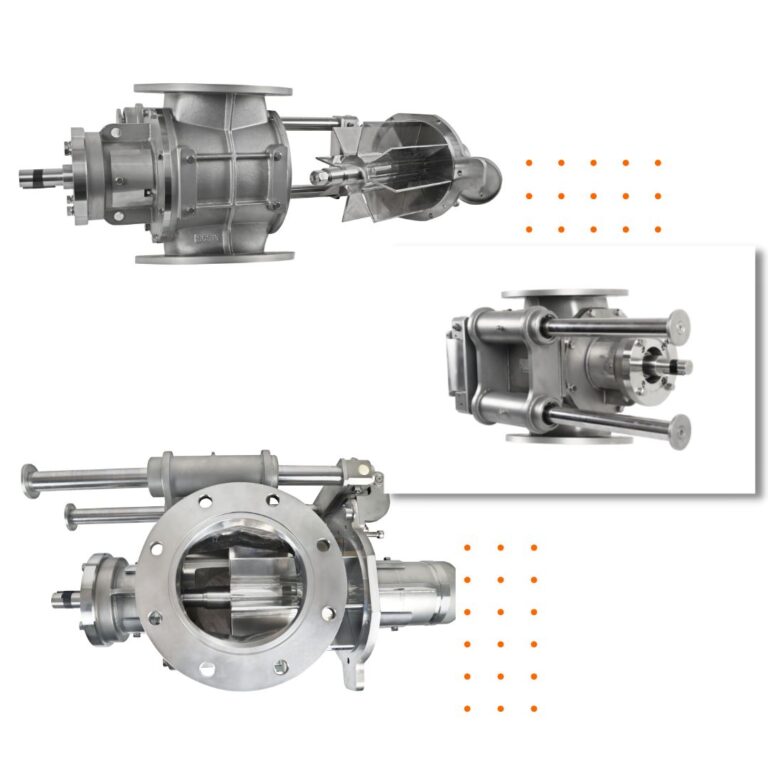

Feeding and Discharge

Rotary valves (also known as rotary airlocks, rotary feeders, etc.) are valves that handle and meter various types powders and granules. Our Rotary Valves are able to hanlde various dry, sticky, corrosive, abrasive powders and granules.

Aishin provides the below Rotary Valves:

- Drop Through type

- Sanitary Type

- Scraper type

- Medium Pressure type

- High Temperature and High Pressure type

- For Dust collector AREX Series

Storage and Unloading

Save Time, Increase Productivity and Efficiency, get rid of powder spillage problems

Particle Sizing & Sifting

High integrity machines for achieving various particle sizing processes; handling everything from bulk agglomerates to micronized material.

Engineering Services

We provide exceptional engineering services for powder handling systems and are experts in the latest powder handling technology. Our team of professionals is dedicated to ensuring efficient and effective design and operation of your powder handling systems.

Our Key Projects: Exceptional attention to smallest details

Latest Projects

How we helped in loading and unloading of spices

- Pneumatic transfer system

- Metal and non-metals removal system

- Intermediate bulk containers – for collection of material

- Pallet truck for conveying material to packing line

End to End execution of pneumatic transfer of variety of solid materials

- Maintaining of filter unit regularly enables longer life span.

- Pleated Filter

- Easy Discharge of Lumpy Material

- Easy Openable Clamps

Reduction of Production Downtime

- Installation of scraper type rotary valve.

- After installation of the scraper type rotary valve, the choking of rotary valve reduced from once in 8 hours to once a week.

- Reduced choking time during material transfer in by 95%.

Certifications

ISO9001 2015Version RB-Q17010

Machinery and Equipment Installation Saitama prefecture Governor Permission(General-22)No.64475