AirSweep Systems: Efficiency Through Bridging Prevention

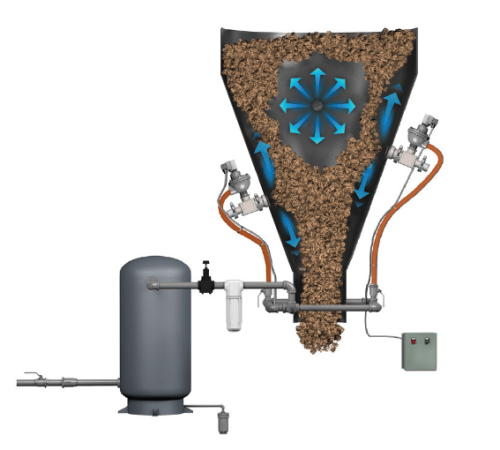

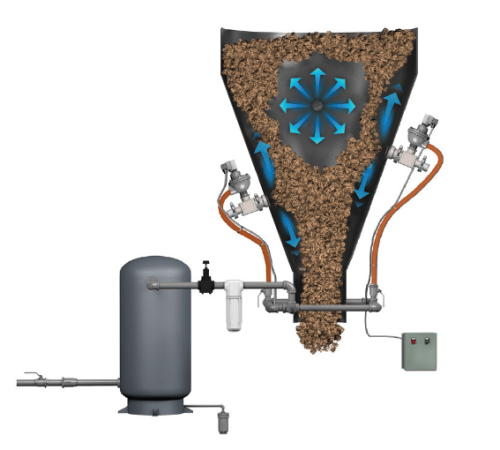

Airsweep® Systems is a material flow solution designed to address and prevent blockages and flow issues in silos, hoppers, chutes, and pipelines. It uses pneumatic technology, using short bursts of high-pressure air to remove obstinate bulk materials.

Uses of Airsweep® Systems

Airsweep® Systems provides a solution for powder flow control, ensuring a steady discharge of powders, granules, and bulk materials while addressing issues like bridging and ratholing. They use a 360-degree burst of compressed air to lift and push obstructed material back into the flow stream, thereby enhancing factory and material handling efficiency. They play a vital role in emptying hoppers and silos efficiently, reducing material waste, and minimizing operational downtimes in industrial processes. Airsweep® systems are also useful for maintaining chutes and conveyor systems, ensuring smooth material flow. This enhances production rates and reduces maintenance costs, making them a valuable tool for optimizing material handling across various industries.

Airsweep® Systems is a material flow solution designed to address and prevent blockages and flow issues in silos, hoppers, chutes, and pipelines. It uses pneumatic technology, using short bursts of high-pressure air to remove obstinate bulk materials.

Uses of Airsweep® Systems

Airsweep® Systems provides a solution for powder flow control, ensuring a steady discharge of powders, granules, and bulk materials while addressing issues like bridging and ratholing. They use a 360-degree burst of compressed air to lift and push obstructed material back into the flow stream, thereby enhancing factory and material handling efficiency. They play a vital role in emptying hoppers and silos efficiently, reducing material waste, and minimizing operational downtimes in industrial processes. Airsweep® systems are also useful for maintaining chutes and conveyor systems, ensuring smooth material flow. This enhances production rates and reduces maintenance costs, making them a valuable tool for optimizing material handling across various industries.

Significance of Airsweep®

Airsweep® Systems are important for multiple reasons. They boost productivity by upholding a constant material flow, reducing production bottlenecks, and costly downtimes. Material wastage is kept to a minimum, safety is amplified by eliminating the necessity for manual interventions in blocked equipment. Importantly, with Airsweep® Systems, you don’t have to resort to using a hammer to discharge powder, making the handling process even more efficient and hassle-free.

Aishin Industrial Corporation and Airsweep® Systems

Aishin Supplies Airsweep® nozzles globally to a wide range of industries. The product is designed to efficiently handle various industrial applications, ensuring optimal performance and reliability. Whether you operate in manufacturing, processing, or any other industry, Airsweep® nozzles can help improve your operational efficiency. This solution helps industries address challenges related to bridging and ratholing issues.

Features

- Minimize downtime for flushing and cleaning between product runs.

- Enhance consistency within batches.

- Prevent vibration, stress, or wear on container walls.

Airsweep® Benefits

- Prevents clogging

- Controlled flow

- Saves cleaning time

- Mounted outside vessel

- No wall damages

Applications

Airsweep® is used in various industries, including food processing, pharmaceuticals, fine chemicals, and handling abrasive materials, to improve material flow and prevent clogs or blockages in bins, silos, hoppers, and other storage or processing equipment.

View Technical Document

F.A.Q.

Have any Question?

Yes, Material Flow Solutions, like Airsweep Systems, exhibit remarkable adaptability across diverse industries and material types, ensuring the seamless handling of materials in various operational scenarios.

Powder Flow Control involves the precise management of material flow, a critical aspect of Airsweep Systems. This control ensures a consistent and uninterrupted flow of materials, averting issues such as irregular discharges or uneven flow rates.

A Pneumatic Flow Aid serves as a complementary device that harmoniously works alongside Airsweep Systems to enhance material flow further. Typically, it employs controlled bursts of air or other pneumatic techniques to address specific flow challenges, guaranteeing the dependable and smooth discharge of materials.

Airsweep Systems play a pivotal role in preventing blockages, optimizing material flow, minimizing downtime, and enhancing production efficiency.

In the pharmaceutical sector, Airsweep systems are indispensable for facilitating the smooth flow of powders and granules, crucial in the production of pharmaceutical products.

AIR SWEEP systems are designed for minimal maintenance, with some routine checks and filter replacements. They are known for their reliability.

Yes, AIR SWEEP systems can often be integrated with existing control and automation systems, allowing for remote operation and monitoring.

Yes, you can add AIR SWEEP to your current storage bins and containers without having to change