Feeding and Powder Discharge: Solutions for Industries

Prevent segregation, clogging and contamination of Powders as well as minimize dust generation

Experience the Precision of Japanese Engineering in Bulk Powder Handling and Storage Solutions

Feeder

A feeder is an equipment designed to supply materials such as powder, granules, solid particles in a controlled and consistent manner to a downstream process or machine. Feeders are commonly used in various industrial applications. The primary function of a feeder is to ensure a continuous and uniform flow of material, optimizing production efficiency and minimizing downtime.

Discharger

A discharger is an equipment used to remove materials or substances from a storage vessel or container. Dischargers are essential in industries where the efficient and controlled emptying of bulk materials, powders, or granules is required, such as silo and hopper. They facilitate the transfer of materials from a source to a destination, allowing for further processing or distribution. Their primary purpose is to ensure the reliable discharge of materials from a storage or transport system, preventing blockages and ensuring a smooth workflow.

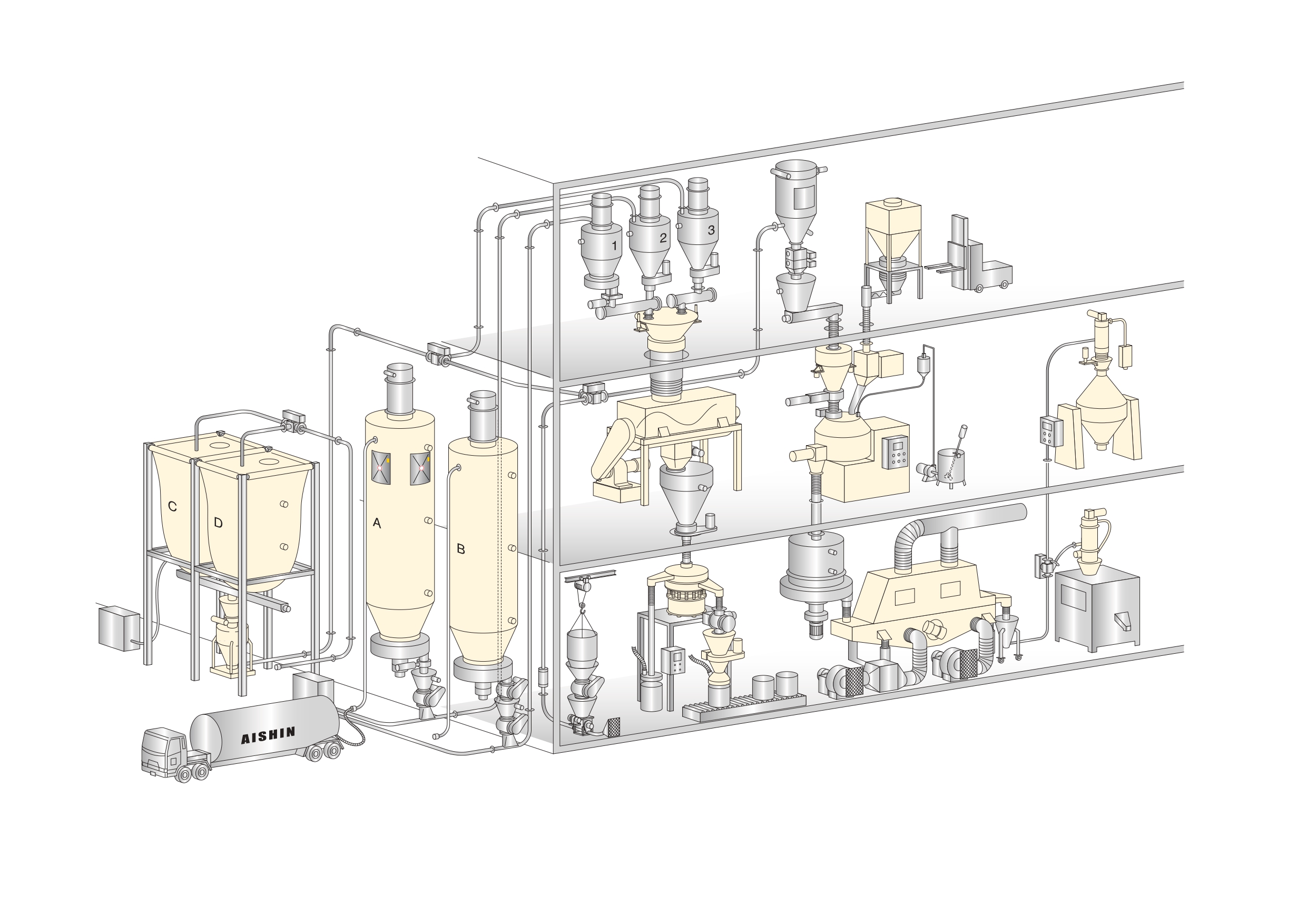

Aishin Industrial Corporations: Material Handling Solution

Aishin designs and manufactures feeder/discharge systems. Pneumatic feeding systems, powder discharge solutions, and powder transfer solutions are some of the technologies we provide. Our expertise includes rotary valves, butterfly valves, knife gate valves, dosing systems, double flap dampers, diverter valves, and bin scrapers, among other components. Our equipment is tailored to the specific requirements of each industry we serve, assuring seamless and reliable material handling operations.

Flow Characteristics

We understand the flow characteristics of the powder and provide custom solution to the problem of material flow

Equipment Design

Design with Japanese engineering emphasizing attention to detail, quality and rigorous standards and disciplined approached to design.

Processing Rate

Effortless Powder Transfer Solutions: We Handle Any Type of Powder for You

Rotary valves, also known as rotary feeders, play a vital role in industries by efficiently controlling the flow of bulk materials, preventing spillage, dust dispersion, and contamination.

A knife gate valve is a type of industrial valve used for on-off and isolation in systems with high-consistency liquids, slurries, or solids. It has a sharp-edged disc that cuts through the material to achieve a tight shut-off.

A diverter valve is a device used for transferring powder and granule materials from one place to another. This device has two outlets and one inlet, designed for a wide range of industrial applications. For their efficiency in handling material flow, two important varieties stand out.

A diverter valve is a device used for transferring powder and granule materials from one place to another. This device has two outlets and one inlet, designed for a wide range of industrial applications. For their efficiency in handling material flow, two important varieties stand out.

A dosing system is used to precisely measure and dispense powdered ingredients in a wide range of industries. These systems are designed to ensure accurate and consistent powder dosage, which is crucial for achieving product quality, meeting regulatory standards, and optimizing manufacturing operations.

Double flap dampers, also known as twin flap dampers, are specialized control devices used in transfer systems to moderate the flow of powders and granular materials. These dampers are made up of two flaps that can be adjusted to control the powder flow volume and direction.

A cross feeder or discharger is the equipment used to move powdered or granular materials within a processing or manufacturing system. These devices are essential for controlled powder movement in industrial applications like pharmaceuticals, batteries, chemicals, food items, and others.

Bin scrapers are used to facilitate the efficient discharge of flowing powders from hoppers or silos. This device is essential for maintaining the steady flow of powdered materials in various industrial applications.