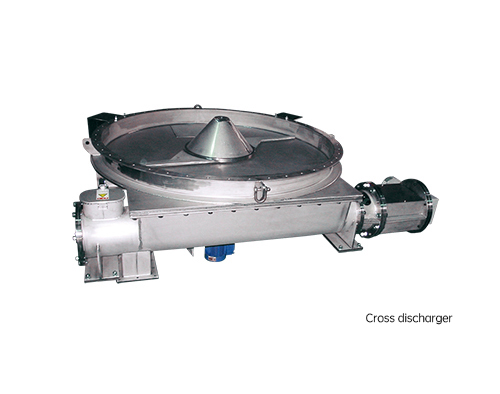

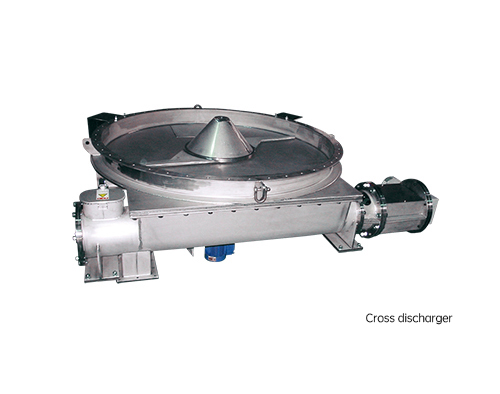

Cross Feeder / Discharge

Role of Cross Feeders in Powder Transfer System

A cross feeder’s importance in industrial processes comes from its ability to ensure consistent and reliable powder discharge, which is essential in ensuring a smooth and uninterrupted production flow. Irregular discharge can lead to operational disturbances, disrupt downstream operations, and potentially damage equipment.

A cross-feeder or discharger is the equipment used to move powdered or granular materials within a processing or manufacturing system. These devices are essential for controlled powder movement in industrial applications like pharmaceuticals, batteries, chemicals, food items, and others.

The Aishin cross-feeder is connected to the hopper, allowing material to flow into it. Inside the feeder, blades move in an anticlockwise direction, helping to evenly distribute the material. This efficient system features a cone-shaped structure at the center of the cross feeder, designed to prevent blockages and clogs while ensuring a consistent flow of powder material. At the end of the process, there is a discharging point where the material is released for further processing.

Features

- The cross-discharger facilitates the discharge of bulk materials from large-sized silos and hoppers.

- Cross feeder/discharger is used to discharge powder/slurries with poor flow characteristics at a fixed rate from silos/hoppers

- Easy design solving major discharge problems increasing the productivity of the plant

Benefits

- Uniform powder discharge

- Operational efficiency

- Equipment protection

- Material handling precision

- Prevention of clogs

Features

- The cross-discharger facilitates the discharge of bulk materials from large-sized silos and hoppers.

- Cross feeder/discharger is used to discharge powder/slurries with poor flow characteristics at a fixed rate from silos/hoppers

- Easy design solving major discharge problems increasing the productivity of the plant

Benefits

- Uniform powder discharge

- Operational efficiency

- Equipment protection

- Material handling precision

- Prevention of clogs

Applications

The feeders/dischargers are used in a variety of sectors to facilitate effective material handling and ensure a smooth manufacturing process. The discharger have industrial applications in the battery, chemical, food industries and others.

About Aishin industrial corporation

Aishin specializes in industrial valves and equipment. We prioritize efficient material handling in industrial processes. Our headquarters are in India and Japan, and we focus on providing effective solutions to enhance material handling system efficiency and reliability. We incorporate cross-feeders into our product range to improve industrial processes.

F.A.Q.

Have any Question?

Powder discharge through cross feeder/discharger is a process used in various industries to efficiently and evenly dispense powdered materials from storage vessels, such as silos or hoppers, to downstream processing or packaging equipment.

Costs can vary significantly depending on size, customization, and features, you can contact us to know the pricing

Yes, they can handle materials with varying sizes and densities, with adjustments as needed.

Yes, they can be designed for food-grade applications with sanitary materials and designs

To maintain a Cross Feeder/Discharger, regularly inspect and lubricate moving parts, check for wear and tear, and ensure proper alignment for efficient material transfer.