About Us

Established in 1972, Aishin Industrial Corporation has solidified its position as a global leader in powder material handling epuipment, material processing, and powder transfer systems. Rooted in Tokyo, Japan, Aishin has diligently expanded its presence to cater to evolving market demands worldwide. Presently, it has manufacturing facilities not only in Japan but also in India, Thailand, and China, becoming a significant player in powder handling epuipment and powder transfer system manufacturers in India and globally. Aishin takes immense pride in having delivered over 300,000 units of bulk powder handling systems to a wide spectrum of industries.

In 1947, Gansons embarked on a journey to create the world’s best processing equipment, earning a revered reputation within the industry.

Enhance Efficiency with Powder Transfer System

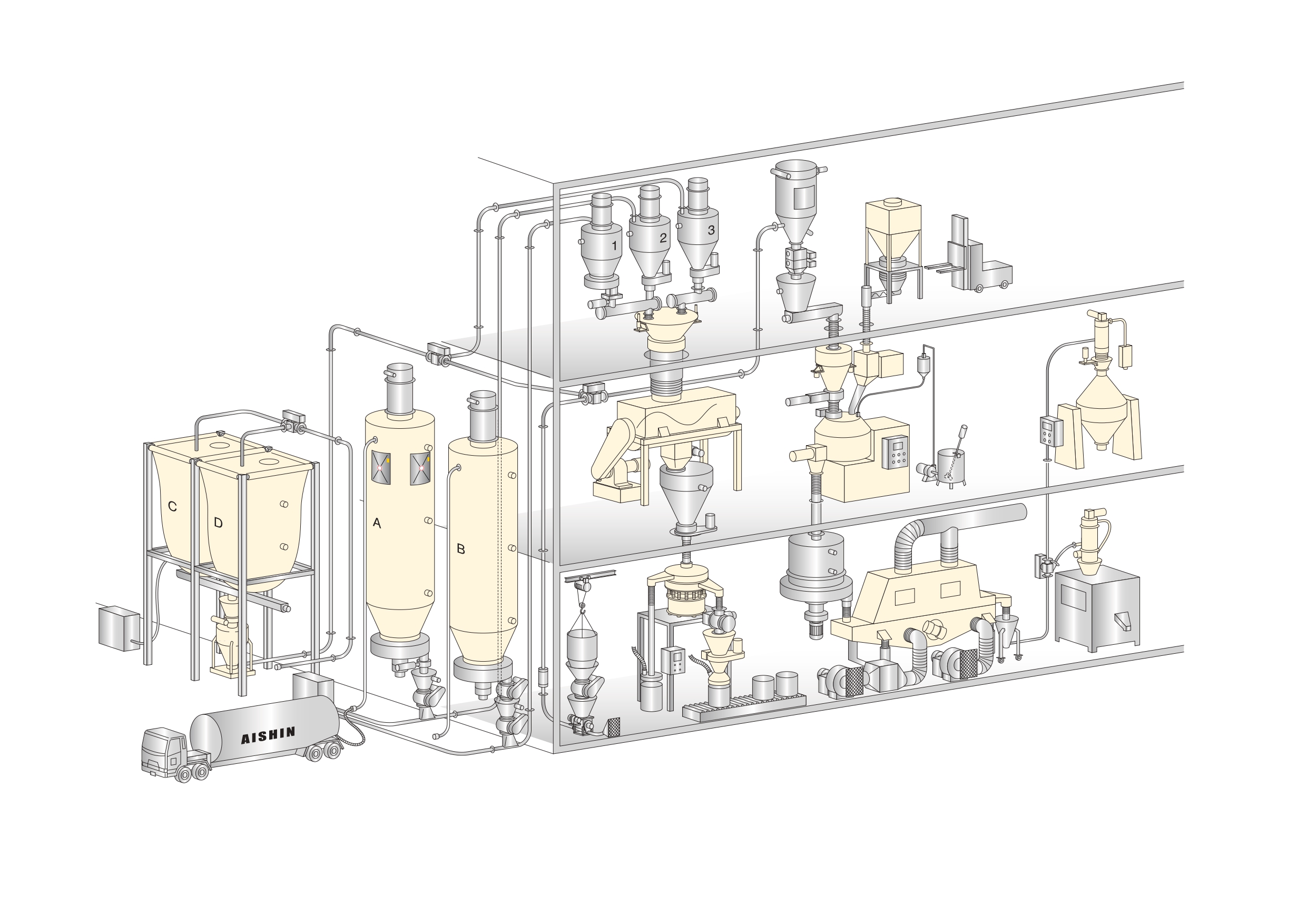

A Powder Transfer System is a specialized solution designed to transfer bulk powders efficiently and safely within manufacturing process. These systems are vital for maintaining material integrity, reducing contamination risks, and ensuring seamless operations in industries.

We specialize in the design, manufacturing, and supply of bulk powder transfer systems tailored to industrial needs. Our solutions ensure efficient, safe, and contamination-free handling of powders across various applications, enhancing productivity and maintaining material integrity.

With a focus on precision and durability, our systems are Japanese-engineered to address diverse challenges in powder processing and conveying. Whether for pneumatic powder transfer, vacuum systems, or custom configurations, we offer dependable solutions built for seamless integration into your operations.

Your partner to achieve precise Powder handling solutions

The union of Gansons and Aishin Industrial Corporation gave rise to Aishin Global, a collaborative venture formed to address the growing demand for bulk powder material handling equipment in India and global markets. This partnership highlights the combination of advanced technology with the highest standards of design and engineering, emphasizing efficient processing.

Our engineering team is recognized for its Japanese precision and innovation, ensuring the quality craftsmanship and performance of our powder transfer systems that distinguish us in the industry.

How we executed one of the largest project for powder handling in FMCG?

We specialize in addressing powder-related challenges for a diverse range of industries, including:

Warranty

Proin ex ipsum facilisis id tincidunt sed vulputate in lacus donec pharetra.

Responsibility

Proin ex ipsum facilisis id tincidunt sed vulputate in lacus donec pharetra.

Food industry:

Enhancing efficiency in food processing through tailor-made granule and powder transfer system solutions.

Pharma & API industry:

Delivering precise powder handling solutions for pharmaceutical and API manufacturing.

Chemical industry:

Safely handling chemical powders within the manufacturing process equipment.

Cosmetic industry:

Streamlines powder product processing for consistency.

Mining and metal industry:

Confronting heavy-duty material handling challenges.

FMCG (fast-moving consumer goods):

Ensuring precise, consistent formulation and reducing waste.”

Food Industry

Pharma & API industry

Electronics Industry

Plastics industry

Chemicals industry

Cosmetics Industry

Mining and Metals industry

FMCG

Our values - committed to the Japanese way:

We believe in delivering perfection in everything we do, which requires a focus on even the smallest details to ensure excellence in our products and services.

A relentless pursuit of perfection. Meticulous craftsmanship

Contact Us

We are ready to help you with your Powder handling problems.

Locate Us

Exceptional attention to smallest details

Explore the following case study, which unveils how our engineering expertise and machinery has significantly contributed to reducing downtime while enhancing production and performance efficiency. These case studies delve deeply into the challenges encountered, the strategies employed, and the impressive outcomes realized.

How we achieved High-Capacity Pneumatic Transfer System of Powders (HUL)

- Continuous pneumatic Transfer System with Double Flap valves

- Small height Big Bag Dumping Station (Limited plant height availability) with Vibrators for easy material flow

- Long Cylindrical Filter bags for Air-material separation